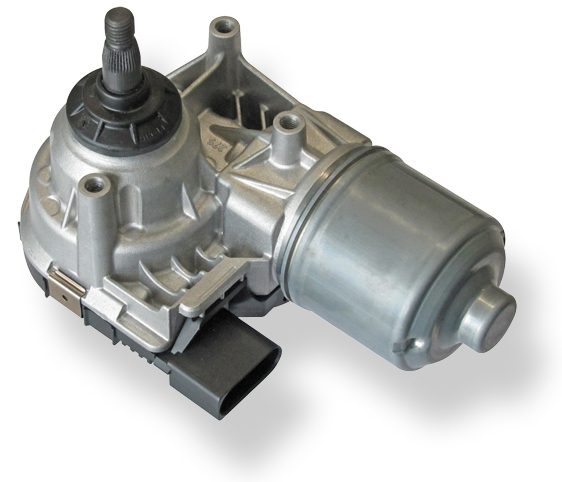

The WDA is a wiper motor designed to execute reversing movements instead of rotating 360° like a conventional wiper.

Its function and many operating modes are managed by integrated control electronics. The user is able to control the desired operating mode simply by switching its analog inputs to ground (Analog version) or via LIN (LIN version). The gear, the motor and the electronics are all installed in the same housing.

The main benefit of this wiper motor is its direct rotation movement which replaces external gears and the possibility of programming the operating speed and end positions of all its function modes, upon request.

- Downloads

- Features

- Application

- Technical Specifications

- Installation Notes

- Ordering Information

- Dimensions

- Legal Restrictions

Downloads

Features

- Analog and LIN versions available

- Optimized hardware for motorsport applications

- Customer specific calibration of wiping angles and speed

Application

|

Operating temperature range |

-40 to 85°C |

Technical Specifications

WDA Analog Operating modes |

| |

WDA LIN Operating modes |

| |

Mechanical Data

Size | 104.7 x 174.7 x 117.1 mm |

Max. wipe cycles/min | Depending on wipe angle |

Max. wipe angle | 160° |

Max. torque | 35 Nm |

Weight | 1,270 g |

Max. vibration | 30 % of Vibration Profile 1 |

Electrical Data

Power supply | 9 to 16 V |

Supply current at 40 cycles/min. | Typ. 3.4 A |

Supply current at 60 cycles/min. | Typ. 6.3 A |

LIN Protocol

LIN Version | 2.0 | ||||||||||||

LIN Speed | 19.2 kbaud | ||||||||||||

Message ID | 0x31 | ||||||||||||

BYTE 0 Value | 0 | 0 | Kl. X | Kl. 15 | Counter | ||||||||

Bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | |||||

|

|

|

|

|

|

|

|

| |||||

BYTE 1 Value | SPD2 | SPD1 | INT | SST | INT Mode | ||||||||

Bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | |||||

|

|

|

|

|

|

|

|

| |||||

BYTE 2 Value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||

Bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | |||||

|

|

|

|

|

|

|

|

| |||||

BYTE 3 Value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||

Bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | |||||

|

|

|

|

|

|

|

|

| |||||

BYTE 4 Value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||

Bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | |||||

|

|

|

|

|

|

|

|

| |||||

BYTE 5 Value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||

Bit | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | |||||

Byte | Bit | Signal | Explanation | Values [dez] | |||||||||

0 | 0 to 3 | Counter | The counter has to be increased with each LIN-message | 0 to 15 | |||||||||

0 | 4 | Kl. 15 | Clamp 15 Bit has to be enabled for operation | ON=1 | |||||||||

0 | 5 | Kl. X | Clamp X Bit has to be enabled for operation | ON=1 | |||||||||

1 | 0 to 3 | INT Mode | Interval Mode (enabled if operation mode interval is set) | Interval speed: | |||||||||

1 | 4 | SST | Single stroke operation mode (enabled once if Bit is set temporary) | ON=1 | |||||||||

1 | 5 | INT | Operation mode interval | ON=1 | |||||||||

1 | 6 | SPD1 | Operation mode speed 1 | ON=1 | |||||||||

1 | 7 | SPD2 | Operation mode speed 2 | ON=1 | |||||||||

|

| STOP | Operation mode stop is enabled if SST, INT, SPD1 and SPD2 are OFF (default) |

| |||||||||

Connectors and Wires

Connector | CEP2M-AMP-4 |

Mating connector | F02U.B00.542-01 |

Various motorsport and automotive connectors available on request | |

Pinout Analog

Pin 1 | AN2 |

Pin 2 | AN1 |

Pin 3 | Gnd |

Pin 4 | US |

Pinout LIN

Pin 1 | LIN |

Pin 2 | Not connected |

Pin 3 | Gnd |

Pin 4 | US |

Installation Notes

Typical lifetime: max. 220 h / 1 year |

For application with severe conditions and/or high volume, please contact your Bosch Motorsport counterpart in order to define the most appropriate validation program |

The WDA Analog can be operated by switching the analog inputs between ground and voltage supply. |

The WDA LIN can be operated by all ECUs with LIN 2.X Master function. Further information about the LIN-Frame available upon request. |

Make sure that the wiper is in its workspace when restarting after a power failure (upper and lower limit). |

Please contact us to define the desired angle of all the operating modes. |

The acceleration values can be exceeded by using silentblocks (F02U 003 027-01). |

Please ensure that the environmental conditions do not exceed the specifications. |

Please find further application hints in the offer drawing at our homepage. |

Please deliver the calibration sheet with your order placement. |

LIN ID 0x32 (Tx) is used for internal WDA diacnostic porpouses. Make sure that the LIN ID 0x32 is not used in your LIN network by any other device. |

Delivery Status

The motor will be delivered with three mounting screws. The screws are pre-assembled with a few thread turns.

|

Ordering Information

WDA LIN

Order number: F02U.V00.838-04

WDA Analog

Order number: F02U.V00.938-03

Accessories

Silentblock

Order number: F02U.003.027-01

Dimensions

Legal Restrictions

Due to embargo restrictions, sale of this product in Russia, Belarus, Iran, Syria, and North Korea is prohibited.